| Product | Product Id | Type | Rotation | Inside Diameter | Outer Diameter | Height | Material | Housing Material | Spring | Dust lip | Color | Stock | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

44083 | Oil Seal | 25.4 | 45.24 | 11.91 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,95 | Details | Quote | |

|

44082 | Oil Seal | 22.22 | 34.92 | 4.76 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,69 | Details | Quote | |

|

44081 | Oil Seal | 22.22 | 28.57 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 422 | € 0,62 | Details | ||

|

44080 | Oil Seal | 19.05 | 31.75 | 6.35 | NBR - Nitrile | Steel | No | No | Black | 0 | € 3,05 | Details | Quote | |

|

44079 | Oil Seal | 19.05 | 31.75 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 0 | € 3,05 | Details | Quote | |

|

44078 | Oil Seal | 19.05 | 28.57 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 1019 | € 0,62 | Details | ||

|

44077 | Oil Seal | 19.05 | 27 | 4.6 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,62 | Details | Quote | |

|

44076 | Oil Seal | 17.46 | 25.4 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,62 | Details | Quote | |

|

44075 | Oil Seal | 17.46 | 22.22 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,58 | Details | Quote | |

|

44074 | Oil Seal | 15.87 | 23.81 | 4.76 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,58 | Details | Quote | |

|

44073 | Oil Seal | 12.7 | 17.46 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 1608 | € 0,58 | Details | ||

|

44072 | Oil Seal | 11.11 | 20.98 | 4.76 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,58 | Details | Quote | |

|

44071 | Oil Seal | 11.11 | 19.05 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,58 | Details | Quote | |

|

44063 | Oil Seal | 65 | 88 | 6 | NBR - Nitrile | Steel | No | No | Black | 5 | € 8,16 | Details | ||

|

44001 | Oil Seal | 47.62 | 63.65 | 6.35 | NBR - Nitrile | Steel | No | No | Black | 0 | € 1,40 | Details | Quote | |

|

43982 | Oil Seal | 19.05 | 25.4 | 3.17 | NBR - Nitrile | Steel | No | No | Black | 1794 | € 2,65 | Details | ||

|

43981 | Oil Seal | 15 | 28 | 3 | NBR - Nitrile | Steel | No | No | Black | 311 | € 2,65 | Details | ||

|

43980 | Oil Seal | 15 | 24.5 | 5 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,58 | Details | Quote | |

|

43979 | Oil Seal | 14 | 24 | 4 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,58 | Details | Quote | |

|

43978 | Oil Seal | 13 | 25 | 7 | NBR - Nitrile | Steel | No | No | Black | 0 | € 0,58 | Details | Quote | |

|

43973 | Oil Seal | 16 | 25 | 4 | NBR - Nitrile | Steel | No | No | Black | 2255 | € 2,65 | Details | ||

|

43810 | Oil Seal | 20 | 26 | 4 | NBR - Nitrile | Steel | No | No | Black | 866 | € 0,62 | Details | ||

|

43804 | Oil Seal | 27 | 34 | 3 | NBR - Nitrile | Steel | No | No | Black | 414 | € 3,05 | Details | ||

|

43791 | Oil Seal | 30 | 40 | 4 | NBR - Nitrile | Steel | No | No | Black | 1299 | € 1,76 | Details | ||

|

43790 | Oil Seal | 15 | 21 | 2 | NBR - Nitrile | Steel | No | No | Black | 1536 | € 0,58 | Details | ||

|

43789 | Oil Seal | 15 | 21 | 3 | NBR - Nitrile | Steel | No | No | Black | 870 | € 0,58 | Details | ||

|

43788 | Oil Seal | 12 | 19 | 3 | NBR - Nitrile | Steel | No | No | Black | 487 | € 0,58 | Details | ||

|

43787 | Oil Seal | 10 | 17 | 3 | NBR - Nitrile | Steel | No | No | Black | 3667 | € 2,65 | Details | ||

|

43786 | Oil Seal | 8 | 15 | 3 | NBR - Nitrile | Steel | No | No | Black | 1936 | € 0,58 | Details | ||

|

43587 | Oil Seal | 53.97 | 73.02 | 6.35 | NBR - Nitrile | Steel | No | No | Black | 659 | € 6,52 | Details |

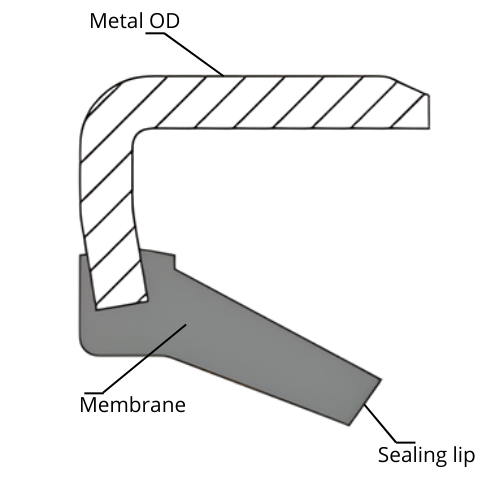

A VB oil seal is a springless rotary shaft seal with a metal outer diameter, developed for applications where low friction, stable seating and reliable grease retention are essential. Unlike a standard radial shaft seal with a garter spring, the VB rotary shaft seal relies entirely on the geometry and elasticity of its single sealing lip to create contact pressure against the shaft. This springless design eliminates excessive lip load, resulting in a consistent, energy-efficient seal that rotates smoothly and performs exceptionally well at higher circumferential speeds without significant heat buildup. The rigid metal OD prevents deformation, ensures a uniform press-fit in the housing and keeps the seal stable, even at larger diameters. For these reasons, this type of seal is ideally suited for clean, pressureless mechanical systems such as electric motors, internal transmissions, fans and other enclosed drive assemblies where a light but reliable sealing solution is required.

The VB oil seal is selected for applications where reliable grease sealing, minimal wear and a low-friction design are priorities. Because it is a springless oil seal, the lip operates with lower and more consistent contact pressure than seals with a spring or dual lip, reducing friction during operation. This makes the oil seal VB particularly suitable for electric motors, fans, small gear reducers, transmissions and various industrial drive systems where smooth, efficient rotation is desired. In closed mechanical housings. such as gearboxes, bearing carriers or internal pump compartments, the VB oil seal effectively retains grease and oil without requiring increased sealing pressure to keep the lip stable. The metal outer diameter also contributes to a firm, accurate press-fit and excellent shape stability, especially at larger diameters or in applications where vibration may occur.

A VB oil seal consists of a metal outer case that is pressed securely and dimensionally stable into the housing, combined with an elastomer sealing lip that dynamically seals against the rotating shaft. This construction provides a stable and durable sealing function, especially in clean environments where a metal-cased oil seal must maintain its geometry for long periods without deformation. The sealing lip is typically made from NBR for standard oils, greases and general industrial lubrication, while FKM is chosen when the seal is exposed to higher operating temperatures or chemically more aggressive lubricants. In applications requiring improved ozone or weather resistance, CR can be used, whereas EPDM is selected when compatibility with brake fluids, water-based media or certain synthetic lubricants is required. For more demanding or specialized environments, ACM or HNBR may also be applied, for example when enhanced heat resistance, ozone resistance or compatibility with modern synthetic fluids is essential. Because the design is completely springless, the profile remains slim, generates less heat and provides a low-friction sealing function that is especially well-suited for equipment operating continuously and at consistent speed.

| Material | Temperature Range | Media Compatibility | Typical Advantages |

|---|---|---|---|

| NBR | –30°C to +100°C | Mineral oils, greases, standard lubricants | Excellent elasticity, low cost, good wear resistance |

| FKM | –20°C to +200°C | High-temperature oils, synthetic lubricants, chemicals | Outstanding heat and chemical resistance, long service life |

| ACM | –20°C to +150°C | Engine oils, ATF, oxidation-resistant fluids | Good heat and ozone resistance, stable at prolonged temperatures |

| HNBR | –30°C to +150°C | Modern lubricants, synthetic oils, ozone, additives | High strength, improved heat and chemical resistance compared to NBR |

| VMQ | –50°C to +180°C | Light oils, greases, low-pressure lubrication | Excellent thermal flexibility and very low friction |

| CR | –40°C to +120°C | Weathering, ozone, moderate oils, mild chemicals | Strong ozone and ageing resistance, good mechanical strength |

| EPDM | –40°C to +150°C | Water-based fluids, steam, brake fluids, polar media | Exceptional weather, ozone and water resistance; ideal for non-oil environments |

The biggest advantage of the oil seal VB is the low friction, that’s what makes this rotary shaft seal VB type suitable for rotating shafts which must rotate smooth and energy efficient. Because the lip has no spring load, less heat builds up at the contact surface, which is especially beneficial for continuously rotating shafts or higher speeds. The metal outer diameter helps maintain a stable positioning, precise interference fit and high dimensional stability, which is essential to machines where vibrations or temperature changes are present. Because the sealing lip functions purely through material elasticity, it wears more slowly and, provided proper lubrication is maintained, remains reliable for long service periods without noticeable performance loss. The trade-off of this springless design is that a VB oil seal is not suitable for pressure, tolerates only limited shaft misalignment and is more sensitive to contamination than designs with a dust lip. For that reason, the oil sealVB is primarily used as a grease seal in clean or internal housings where the operating environment can be controlled effectively.

VB oil seals are used across a wide range of machinery where grease or lubricant must be retained effectively without requiring a spring-loaded sealing mechanism. They are commonly applied in electric motors, small gearboxes, industrial pumps, internal transmission components, fans, generators and various mechanical drive assemblies where a stable, low-friction seal is required. VB oil seals also appear in agricultural machinery and mobile equipment, particularly in protected internal sections where contamination is limited. In all these applications, the low heat generation, high dimensional stability and structural rigidity of a metal OD oil seal provide clear advantages. Especially when installed behind an additional barrier, such as a bearing cover, dust cap, V-ring or labyrinth seal, an oil seal VB can operate reliably for many years without performance loss, since the combination of protection and low friction significantly extends its service life.

|

Brands |

Names/Codes |

|

Dichtomatik |

WBO |

|

AnySeals |

OS-B12 |

|

B+S |

TR-G |

|

Elring |

B OF |

|

Eriks |

MZV |

|

FST |

B1 OF |

|

Kaco |

DC |

|

Kramp |

BD |

|

Stefa |

BD |

|

Taiwan / NOK |

VB |

|

Vota |

B1 OF |

|

Kimman |

KBO |

No. A VB seal is designed for pressureless applications. It retains grease or oil but is not suitable for system pressure.

A VB seal has a metal outer diameter, while a VC seal features a rubber-coated OD. VB is more rigid; VC provides better static sealing in softer housings.

The springless design reduces friction and heat generation, allowing the seal to perform efficiently at consistent rotational speeds.

Typically NBR for standard oils and greases, and FKM for higher temperatures or chemically aggressive lubricants.

Didn't find the right Oil Seal VB - Rotary Shaft Seal?

Complete the form below and we will help you!